Cases

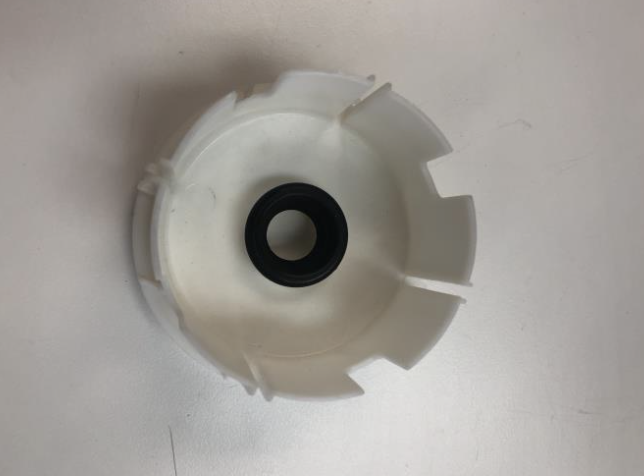

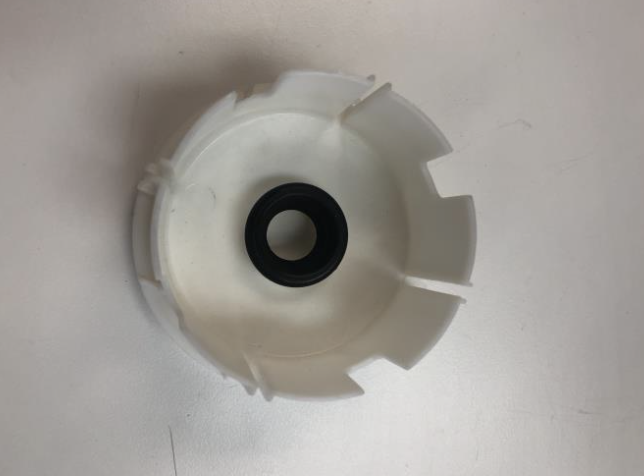

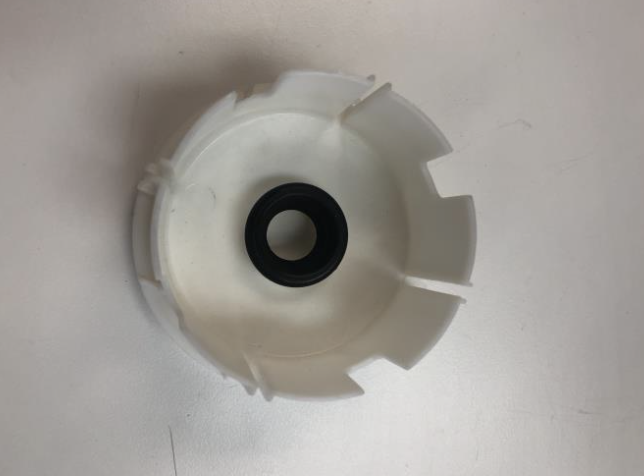

Parker filtration sub-components

Presenting a case on Parker filtration sub-components. This project highlights the precise manufacturing and assembly of filtration sub-components, ensuring reliable performance and high efficiency for Parker’s filtration systems in industrial applications.

F-150 Cabin Air filter assembly

Presenting a case on F-150 cabin air filter assembly. This project focuses on the assembly process of high-quality cabin air filters designed for the F-150, ensuring optimal air quality and system performance in automotive environments.

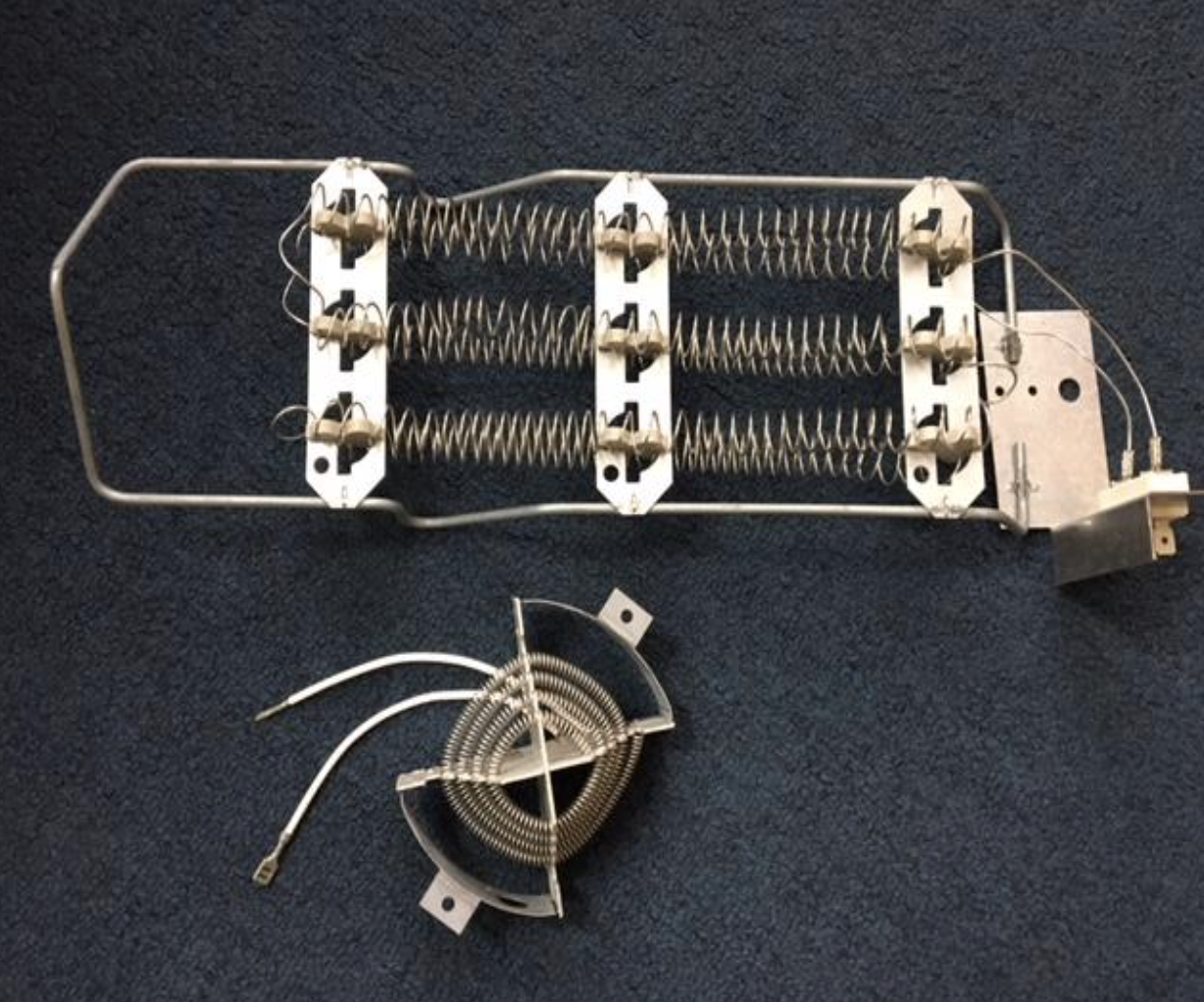

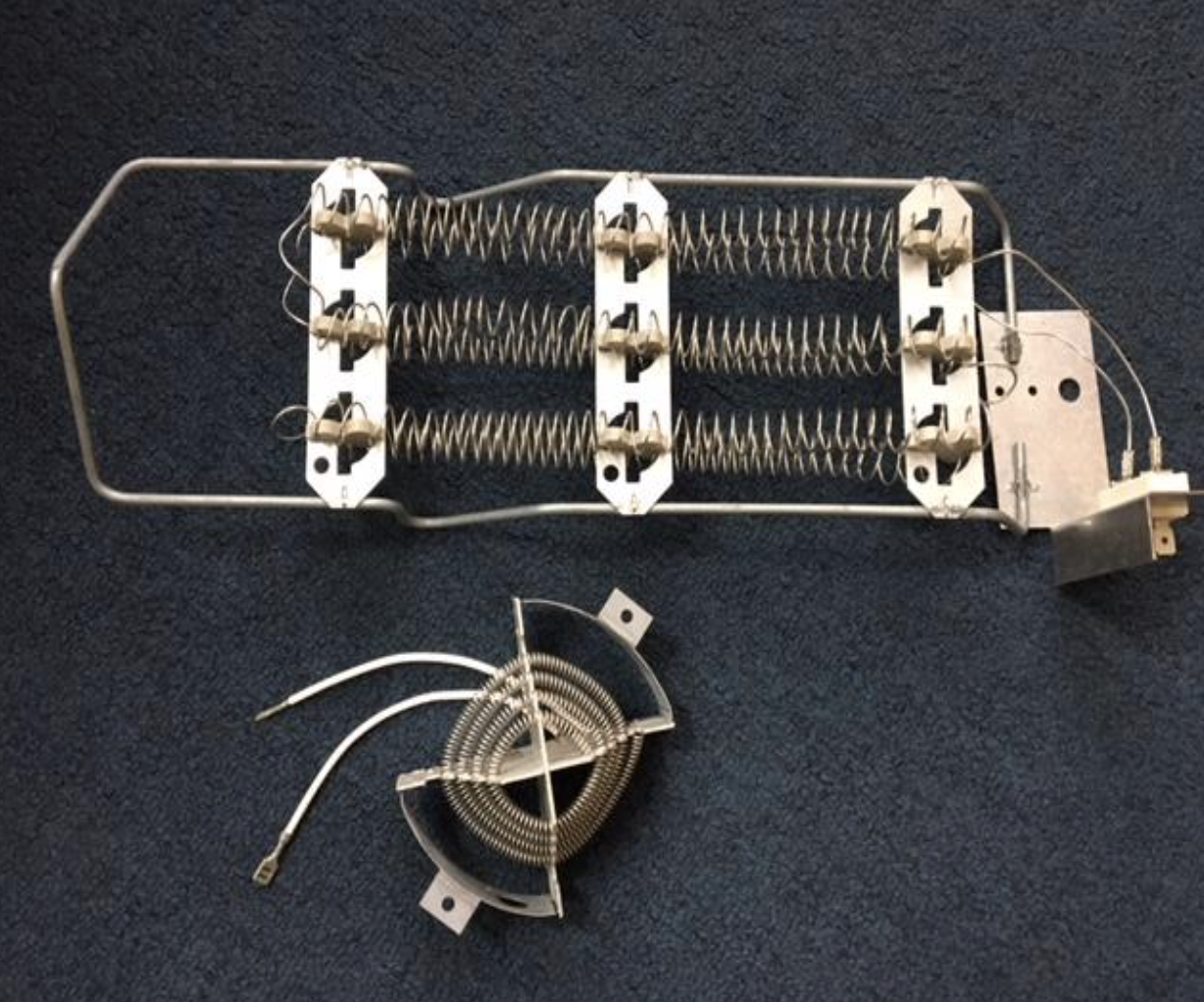

Industrial heating element assemblies

Presenting a case on industrial heating element assemblies. This project showcases the design and assembly of high-performance heating elements, optimized for efficiency and durability in various industrial heating applications.

Idex Corp Power and Data cord Assemblies

Presenting a case on power and data cord assemblies for Idex Corp. This project highlights the design and assembly of high-quality power and data cords, ensuring reliable connections for industrial applications with a focus on durability and performance.

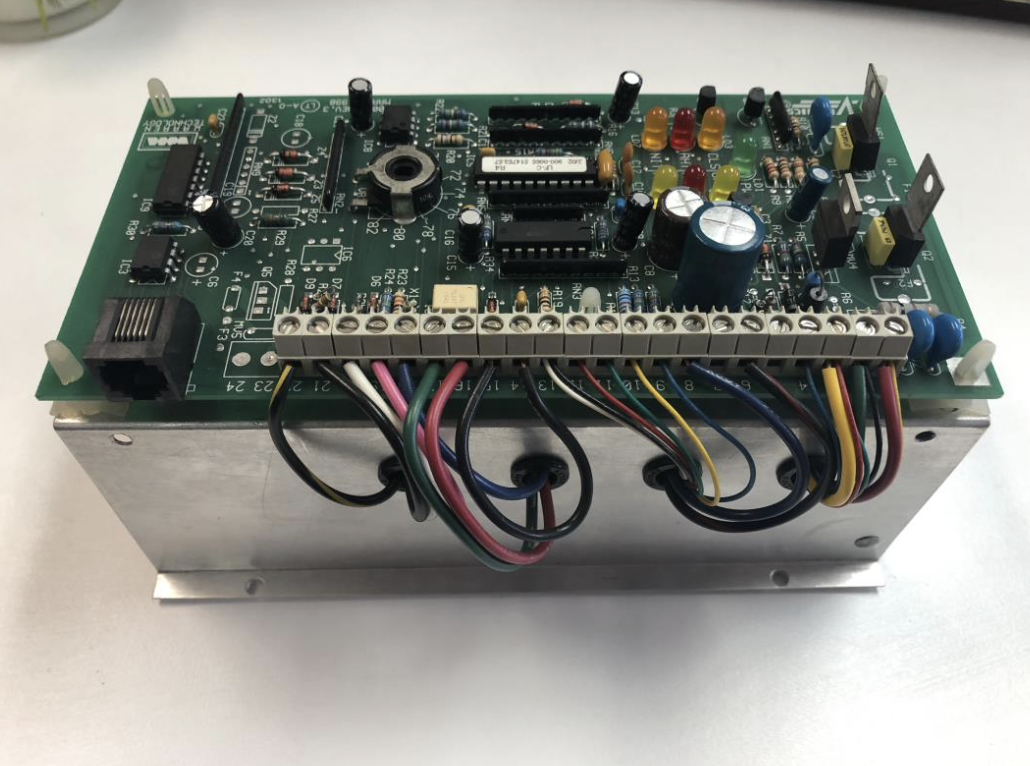

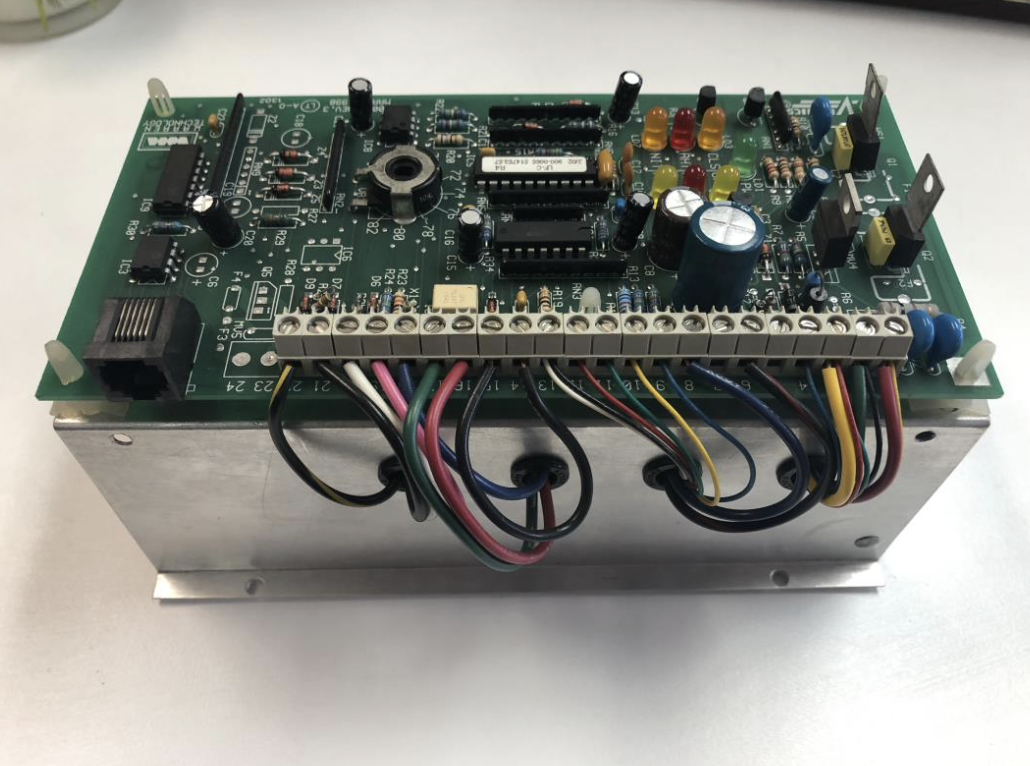

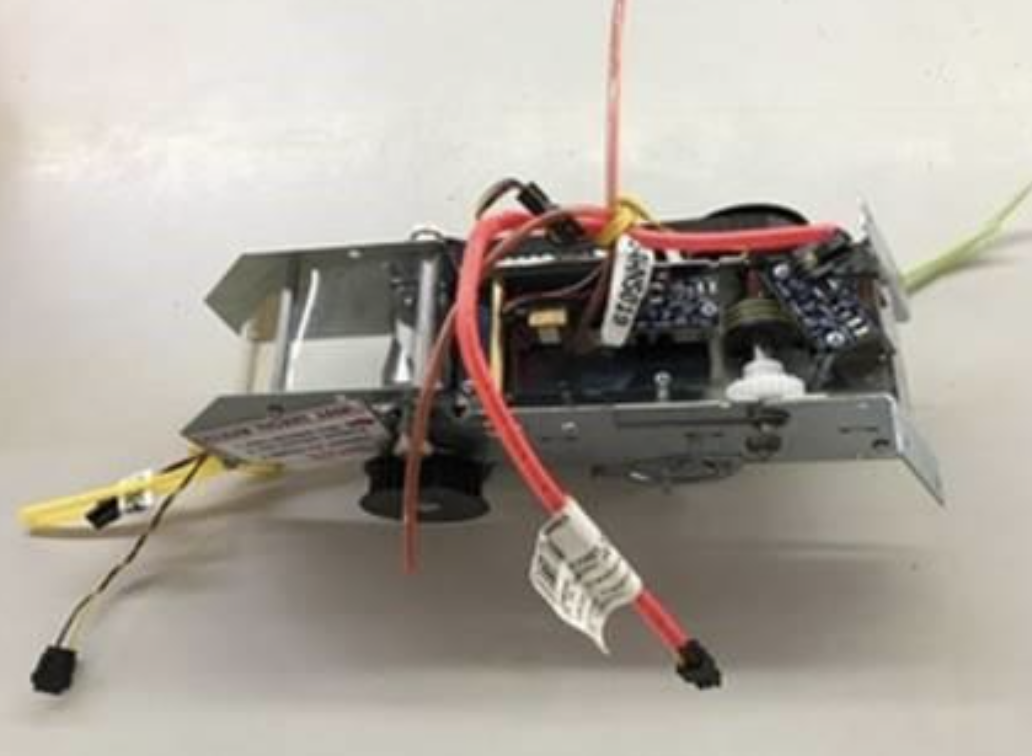

Electro mechanical assemblies

Presenting a case on electro-mechanical assemblies. This project focuses on the integration of electrical and mechanical components to create efficient, reliable systems for various industrial and commercial applications.

Truck Gas Cap Assembly Catapillar & Peterbilt

Presenting a case on truck gas cap assembly for Caterpillar and Peterbilt. This project demonstrates a tailored assembly process designed to meet the specifications of heavy-duty vehicle manufacturers, ensuring durability and reliable performance.

Metal rolling, welding and fabrication

Presenting a case on metal rolling, welding, and fabrication. This project highlights the integration of forming and joining techniques to produce custom metal components with high structural integrity and precision.

Ultrasonic welding

Presenting a case on ultrasonic welding technology. This project showcases the use of high-frequency ultrasonic vibrations to join materials with precision, offering a clean, reliable, and efficient solution for various industrial applications.

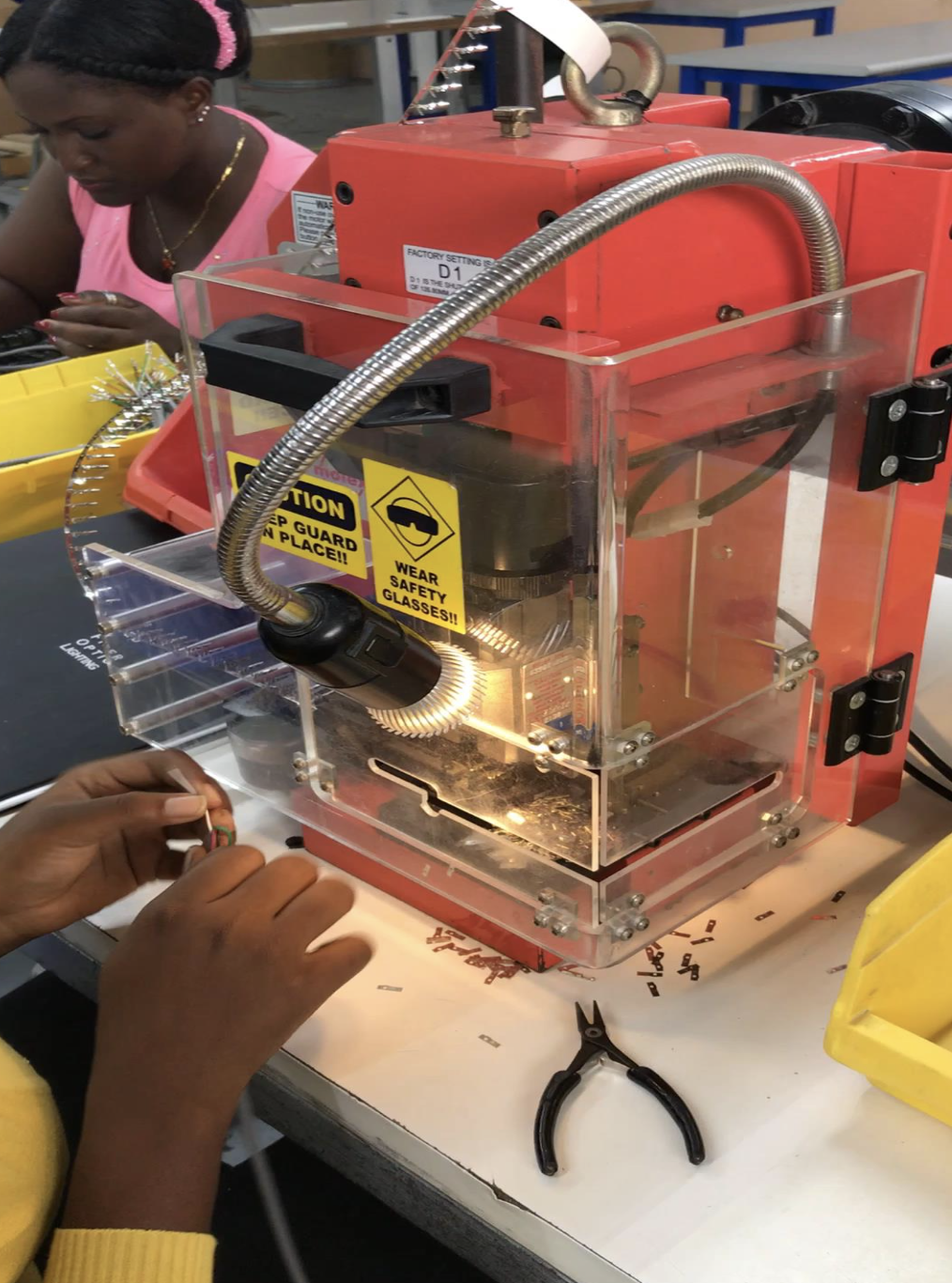

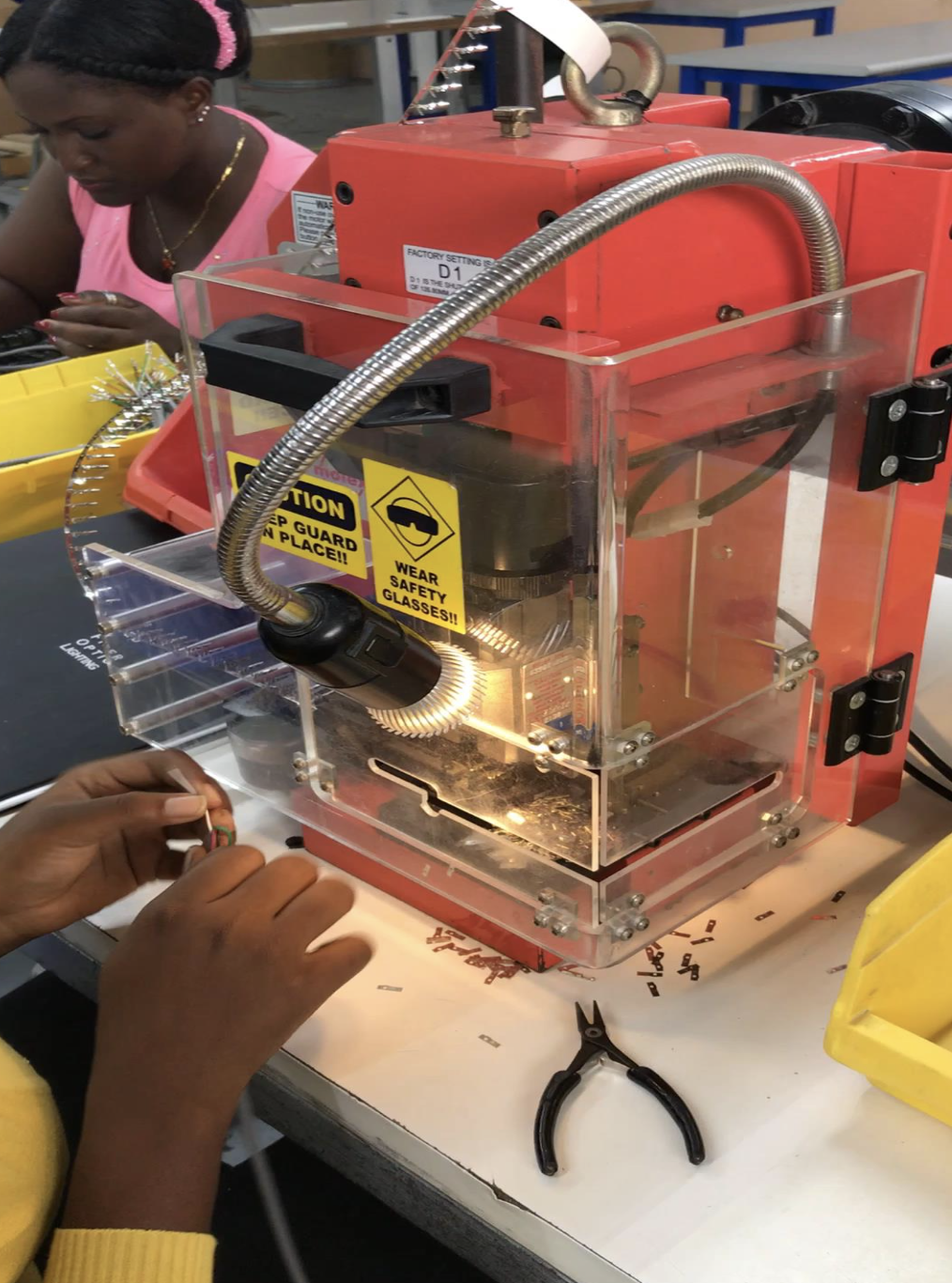

Rocker switch assembly lines

Presenting a case on rocker switch assembly lines. This project features a streamlined and automated process for assembling rocker switches, ensuring consistency, efficiency, and high output quality in line with industry requirements.

Medical assemblies

Presenting a case on medical assemblies. This project highlights the assembly of precision components for medical applications, emphasizing quality, cleanliness, and compliance with industry standards to ensure safe and reliable performance.

Wire Termination and Assembly

Presenting a case on wire termination and assembly processes. This project showcases precise methods for preparing, connecting, and assembling wires, ensuring reliable electrical connections and efficient workflow in production environments.

Automotive Drain Valve Press Assembly and count stations

Presenting a case focused on the press assembly and count stations for automotive drain valves. This project demonstrates a streamlined process for assembling components with precision, supported by integrated counting mechanisms to ensure accuracy and quality control.

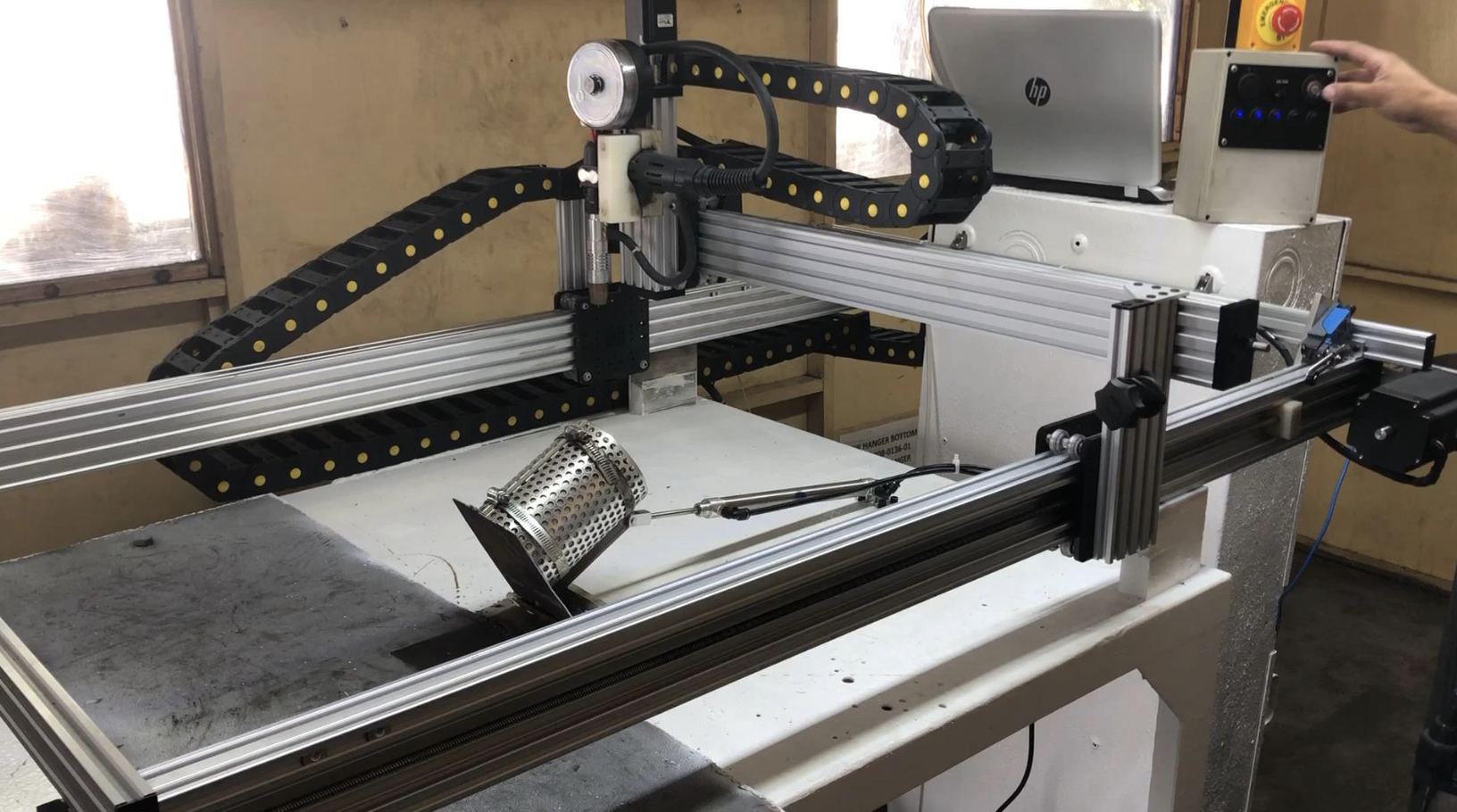

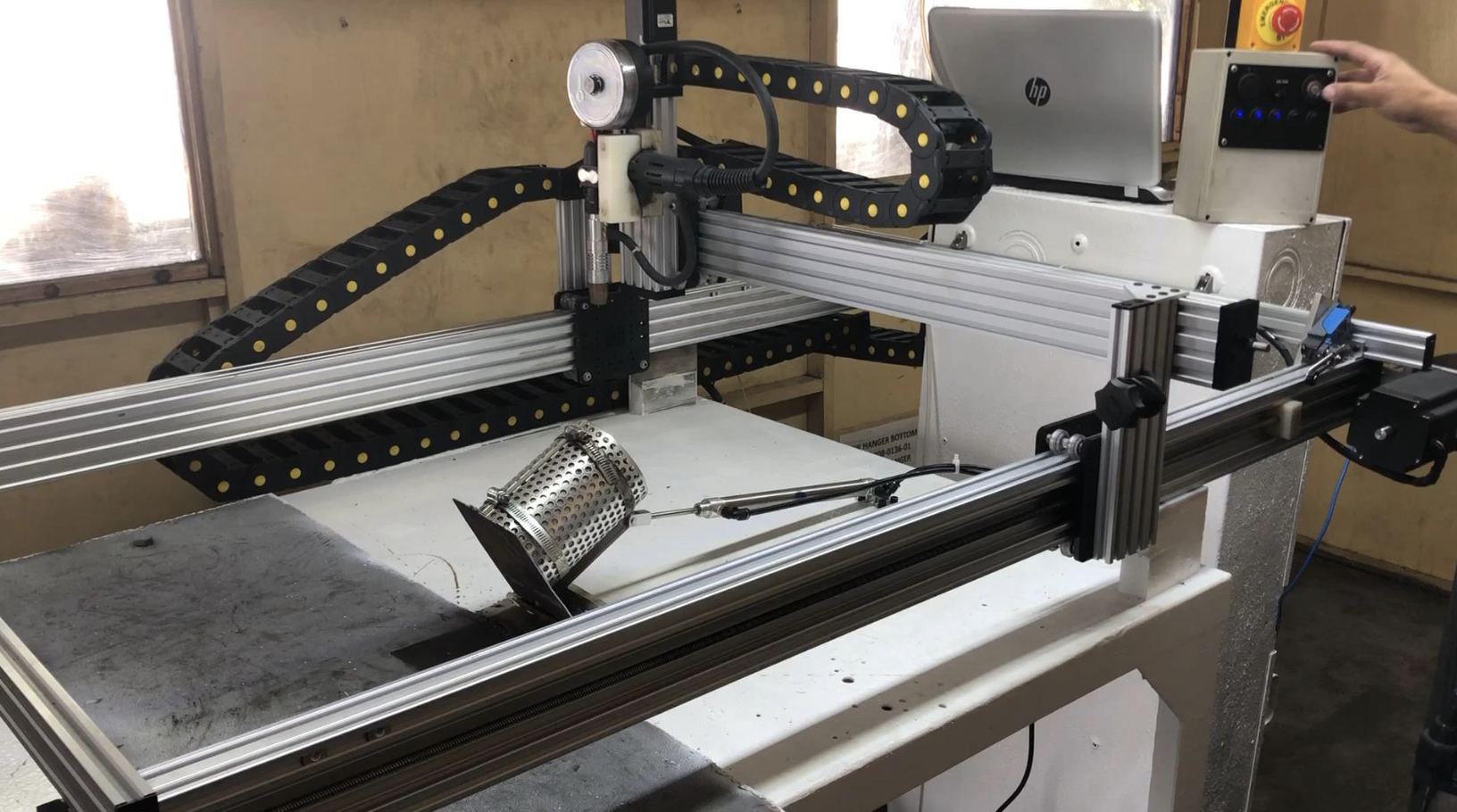

Automated welding

Presenting a case on automated welding solutions. This project highlights the implementation of precision welding techniques using advanced machinery to ensure consistency, efficiency, and high-quality results across different metal types.

Metal forming and fabrication

Presenting a case on metal forming and fabrication processes including punching, bending, and welding. This project showcases the use of 30 T press brakes, sheet metal rollers, and tube forming techniques across various materials like steel, stainless steel, and aluminum.